Streamline Mail Opening and Enhance Efficiency

The next level in automated mail opening, OPEX® OMATION® envelope opening systems will give your mailroom a powerful boost with higher productivity and more efficiency. Our various OMATION systems are designed to meet your workflow’s different and ever-changing needs with advanced features such as printing, sequencing, preset jobs, and additional sort locations.

Introducing OMATION® Model 606™ Envelopener®

Introducing OMATION® Model 606™ Envelopener®

The OMATION® Model 606™ Envelopener® is a high-volume mail processing system that can handle up to 40,000 envelopes per hour. It features cutting-edge technology, an intuitive LCD touchscreen, and an engineered feeder to prevent misfeeds and interruptions. This system provides performance tracking to optimize operations, making mail processing faster, safer, and more efficient.

Meet OMATION® Series 410™ Envelopener®

Low-Volume Mail Opener with Printing & Sequencing

Meet OMATION® Series 210® Envelopener™

Low-Volume Mail Opener

Self-Adjusting Automatic Feeder

OMATION systems have a self-adjusting feeder to accommodate mixed envelope types, sizes, and thicknesses. Easily open standard, thin, thick, airmail, and overnight envelopes all on one platform at a rate of up to 24,000 envelopes per hour on the Series 210 and 410 systems and 40,000 envelopes per hour on the Model 606.

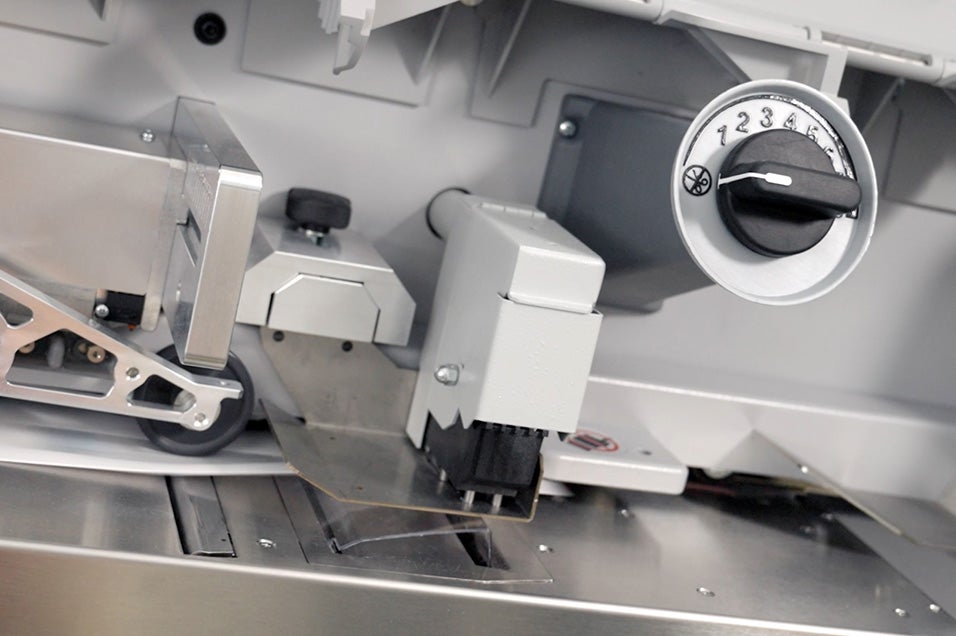

Milling Cutter

All OPEX mail opening systems include specialized milling cutting technology, which chips away as small as 0.01” (0.25 mm) from the edge to create a clean, soft, feathered opening. This method is much safer than using blades. Not only does it significantly reduce paper cuts, but there’s less risk in cutting the envelope contents.

Adjustable Cut Depth

OMATION Series 210 and 410 mail openers have a cut-depth adjustment knob with three optimal cut-depth settings for fine, medium, and heavy-weight envelopes. The OMATION Model 606 system has eight adjustable cut-depths for different envelope weights ranging from 0.01” (0.25 mm) up to 0.125” (3.175 mm). All OMATION systems have a no-cut setting available for envelope counting and sorting.

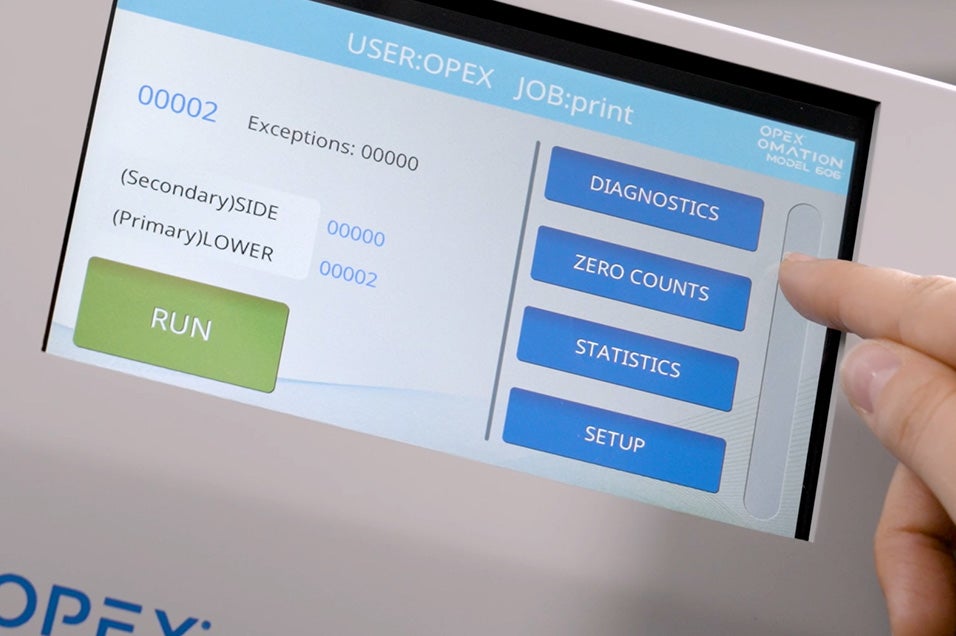

User-Friendly Interface

Easily control the system and view envelope counts with a display and keypad controls on all OMATION systems. For more advanced workflows, the Series 410 opener has a 5.5” (13.94 mm) display for users to choose from eight preset jobs and view envelope counts. The new and improved user-friendly operator-controlled LCD interface on the Model 606 supports numerous job settings, multiple operators, and several languages.

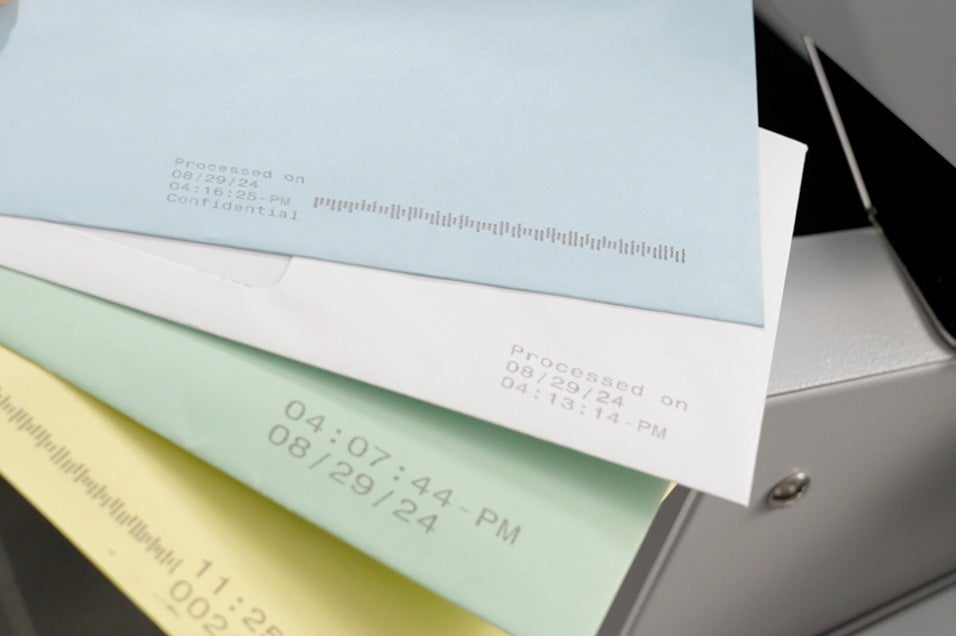

Built-in Printer (Optional)

Print the date, time stamp, and sequence number on each envelope as it passes through the Series 410 system and Model 606 mail openers with a built-in inkjet printer to improve traceability for each mail piece.

Chip Bin/Interlock System

The Series 210 and 410 openers feature a chip bin that allows a maximum of 3,500 envelopes to be opened before emptying. An interlock system prevents the machine from running when the chip bin is removed.

OPTIONAL Sorter

An optional 90° sorting conveyor or sorting bin is available on the Model 606 envelope opener. Making it a perfect fit for applications requiring verification of contents before or after extraction. Envelopes can be sorted into two locations based on programmable criteria such as thickness, length, and height.

|  |

||

|---|---|---|---|

| Length | 1219.2 mm | 1023.6 mm | 1023.6 mm |

| Depth | 514.35 mm | 419.1 mm or 457.2 mm with power cord | 419.1 mm or 457.2 mm with power cord |

| Height | 1492.25 mm | 363.2 mm | 363.2 mm |

| Weight | 106.6 kg (stand & waste bin included) | 24.94 kg | 23.6 kg |

| Speed | Up to 40,000 envelopes per hour | Up to 400 envelopes per minute (152.4 mm envelope) | Up to 400 envelopes per minute (152.4 mm envelope) |

| Envelope Sizes & Types | Lengths up to 342.9 mm. including overnight packs sort capabilities on the first 279.4 mm of envelope | All sizes and types (including overnight envelopes) | All sizes and types (including overnight envelopes) |

| Thickness | up to 12.7 mm envelope thickness | Up to 4.7752 mm envelope thickness | Up to 4.7752 mm envelope thickness |

| Depth of Cut | From 0.3 mm from envelope edge up to 3.2 mm in depth | From 0.254 mm to 1.778 mm | From 0.254 mm to 1.778 mm |

| Electrical Requirements | 115 VAC, 60HZ, 8.5A 3338 BTU/h (115 VAC) 230 VAC, 50HZ, 5.5A 4317 BTU/h (230 VAC) | 110-120 VAC, 60HZ, 5A 1964 BTU/h (max @ 115v/5A) | 110-120 VAC, 60HZ, 5A 1964 BTU/h (max @ 115v/5A) |

| Decibel Rating | Does not exceed safety standard of 80db | Does not exceed safety standard of 80db | |

| Batching | Batching allows operators to group items into pre-selected lot sizes, ensuring maximum productivity by focusing on "clean" batches rather than handling exceptions at the same time. | ||

| 90° Powered Conveyor or Sort Bin | An optional 90° sorting conveyor or sort bin makes the Model 606 envelope opener a perfect fit for applications that require verification of contents either before or after extraction. | ||

| Reports Printer | Produces a variety of statistical reports for monitoring machine performance | ||

| High-Speed Inkjet Printer | Prints a variety of custom strings, including date & time, sequential numbering, ID Tag, and IMB Barcode | Prints date and time audit trails and unique number sequencing for traceable mail |

|  |

||

|---|---|---|---|

| Length | 48 in | 40.3 in | 40.3 in |

| Depth | 21 in | 16.5 in or 18 in with power cord | 16.5 in or 18 in with power cord |

| Height | 58 in | 14.3 in | 14.3 in |

| Weight | 235lbs (stand & waste bin included) | 55 lbs | 52 lbs |

| Speed | Up to 40,000 envelopes per hour | Up to 400 envelopes per minute (6 in envelope) | Up to 400 envelopes per minute (6 in envelope) |

| Envelope Sizes & Types | Lengths up to 13.5 in. including overnight packs sort capabilities on the first 11 in of envelope | All sizes and types (including overnight envelopes) | All sizes and types (including overnight envelopes) |

| Thickness | up to 0.5 in envelope thickness | Up to 0.188 in envelope thickness | Up to 0.188 in envelope thickness |

| Depth of Cut | From 0 - 0.01 in from envelope edge up to 0.125 in in depth | From 0.01 in to 0.07 in | From 0.01 in to 0.07 in |

| Electrical Requirements | 115 VAC, 60HZ, 8.5A 3338 BTU/h (115 VAC) 230 VAC, 50HZ, 5.5A 4317 BTU/h (230 VAC) | 110-120 VAC, 60HZ, 5A 1964 BTU/h (max @ 115v/5A) | 110-120 VAC, 60HZ, 5A 1964 BTU/h (max @ 115v/5A) |

| Decibel Rating | Does not exceed safety standard of 80db | Does not exceed safety standard of 80db | |

| Batching | Batching allows operators to group items into pre-selected lot sizes, ensuring maximum productivity by focusing on "clean" batches rather than handling exceptions at the same time. | ||

| 90° Powered Conveyor or Sort Bin | An optional 90° sorting conveyor or sort bin makes the Model 606 envelope opener a perfect fit for applications that require verification of contents either before or after extraction. | ||

| Reports Printer | Produces a variety of statistical reports for monitoring machine performance | ||

| High-Speed Inkjet Printer | Prints a variety of custom strings, including date & time, sequential numbering, ID Tag, and IMB Barcode | Prints date and time audit trails and unique number sequencing for traceable mail |

Find Out How Omation Can Improve Your Operations

“*” indicates required fields

Increase Productivity with Faster, More Effective Mail Opening

Versatile

Streamline Mail Opening

- Automated mail opening removes the need to rely on letter openers, allowing staff to focus on value-adding tasks.

- Easily open mixed and overfilled envelopes with self-adjusting auto feeders on each OMATION system.

- Adjustable milling cutter depths are available to adapt to the type of mail you need to be opened.

Efficient

Enhance the Efficiency of Your Workflow

- Faster, pain-free mail opening speeds up the entire workflow.

- Specialized milling cutting technology creates a soft, feathered edge that makes removing contents from an envelope easier and minimizes the risk of damaging the envelope contents.

- Additional sorting features available on OMATION Model 606 systems help reduce the need for pre-sorting.

Fast

Increase Productivity

- Automated mail opening allows you to open mail faster, increasing throughput and productivity.

- OMATION Series 210 and 410 systems allow for mail opening up to 24,000 envelopes per hour, or 400 per minute.

- OMATION Model 606 allow mail opening rates up to 40,000 envelopes per hour, or 667 per minute.

Reliable

Minimize Downtime

- Get up and running quickly with fast manufacturing, installation, training, and service provided by OPEX.

- OPEX in-house tech support and service is available to help resolve any issues and perform preventive maintenance to keep downtime at a minimum.

- Keep your workflow moving with faster, automated mail opening and eliminate bottlenecks caused by manual opening.

Secure

Securely Handle Mail

- Additional printing and sequencing features are available on specific OMATION systems to improve mail traceability and accountability.

- Milling-cutting technology helps prevent damage to envelope contents.

Discover How Omation Has Impacted Other Operations

Measure What Matters In Your Warehouse with Performance Analytics

Enhancing Warehouse Efficiency with Automated Buffer Systems

Top 5 Trends in Document Management for 2025

OPEX Service – The Ultimate Partner for Operational Excellence

Automating Kitting Operations

Sure Sort X with Xtract Tote I/O

Last Exit Before Windows 10 End-of-Support: Is Your Document System Ready?

Why Warehouse Automation Service Models Matter

Revolutionizing Manufacturing Warehouses – OPEX® Perfect Pick®

World Class Technology. Local Expertise.

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.