60-Second Summary

Labor costs dominate warehouse expenses and manual processes lead to high error rates and inefficiencies. Automation enhances capacity, throughput, and flexibility, allowing warehouses to adapt to growth, improve order accuracy, and expedite shipping. Financially, automation reduces labor and real estate costs, offers a rapid return on investment, and mitigates risks associated with labor shortages. The post concludes by urging businesses to assess their needs and consider automation to remain competitive and achieve sustainable growth in a rapidly evolving market.

Introduction

The decision to automate is no longer a matter of “if” but “when,” driven by the substantial costs associated with maintaining manual operations. Here, we explore the critical reasons why opting out of warehouse automation can be a costly misstep.

The Current Landscape

The landscape of warehouse management is rapidly changing, with significant pressures on costs and efficiency. Labor costs account for 60-65% of total warehouse fulfillment expenses, excluding shipping, and despite increasing headcounts, productivity hasn’t kept pace. Human error in picking can lead to significant financial drains, costing between $50 and $300 per error. Additionally, rising warehouse space costs and underutilized vertical space exacerbate the challenges.

Inability to Capitalize on Growth Strategy

“If you’re not growing, you’re dying.”

William S. Burroughs

Opting out of automation means missing out on substantial growth opportunities. Automated systems offer unparalleled cubic storage capacity, resulting in smaller warehouses and reduced leasing prices. They are adaptable to both urban and rural settings, providing flexibility in location choice. Automation also enhances capacity and throughput, crucial in a market with labor shortages. It allows for rapid training of new staff, creating a more stable and reliable operational environment.

Capitalizing on Growth Strategy

Automation unlocks the ability to increase throughput and manage higher inventory volumes efficiently. This is especially vital as the e-commerce market grows, projected to reach over $7.9 trillion by 2027. High-performing supply chains, often utilizing automation, consistently outshine competitors in revenue growth.

Growth Considerations: Where?

- Automation can provide unparalleled cubic storage capacity, resulting in smaller warehouses and reduced leasing prices

- Automation is indifferent to location and can be utilized in both urban and rural areas

Growth Considerations: How?

- Automation unlocks the ability to increase capacity and throughput requirements in a market where labor is difficult to find and maintain

- Automation allows management to quickly train new staff, creating a more reliable and stable environment

Distinct Competitive Disadvantage

Automation unlocks the ability to increase throughput and manage higher inventory volumes efficiently. This is especially vital as the e-commerce market grows, projected to reach over $7.9 trillion by 2027. High-performing supply chains, often utilizing automation, consistently outshine competitors in revenue growth.

“If you can’t do it quickly, accurately and efficiently, you’re losing market share to your competition.”

Without automation, warehouses face significant competitive disadvantages. Manual processes lead to slower order cycle times, higher error rates, and inefficiencies that hinder same-day shipping capabilities and inventory control. These issues result in lost market share as competitors with automated systems offer faster and more accurate services.

Service Levels

- Automation results in faster order cycle times, allowing more orders to be processed and the ability to expedite orders

- Faster order cycle time + the ability to expedite orders = increased market share

- Same-day shipping can be achieved by automation through faster pick times

Higher Efficiency and Accuracy

- Approximately 23% of customers issue a return because they received the wrong item, with an estimated cost to process that return at 66% of the product price

Increased product control

- Ability to closely track inventory across the cycle

Financial Considerations

“ROI on automation can be met in as little as two years, even with a multi-million dollar spend.”

Automation leads to direct savings in real estate, utilities, and labor costs. It reduces risks related to labor shortages, absenteeism, and turnover. The return on investment (ROI) for automation can be achieved in as little as two years, even with substantial upfront costs. Enhanced service levels and increased revenue further bolster the financial case for automation (Mordor Intelligence™).

Direct Savings

- Real estate – ownership/rent and utilities

- Labor – wages

- Increased revenue due to enhanced service levels

Reduced Risk

- Absence and job-protected, unpaid leave (FMLA)

- Comp claims

- Turnover and training costs

Opportunities

- Greater bandwidth for more business

- Amplified storage to accommodate additional products

- Ability to capture greater market share

Labor Considerations

“It’s far easier to scale up automation than it is to scale up personnel and their production levels.”

Automation addresses labor challenges by offering predictable costs for equipment, labor, and maintenance. It retains high-quality labor and quickly trains new staff, reducing the dependency on an unpredictable workforce. Automation can also reduce labor requirements by up to 50%, addressing issues like low productivity and workforce shortages.

Dependable costs

- Automation allows for a predictable costing model for equipment, labor and maintenance

Availability and competence

- Automation allows businesses to retain their highest quality labor, and train new labor quickly and efficiently

Morale

- Automation fosters an exciting, futuristic environment employees can take great pride in

- Automation challenges your workforce in positive ways that increase engagement and allow employees to thrive

Should You Automate Your Warehouse?

Assessing Your Own Needs

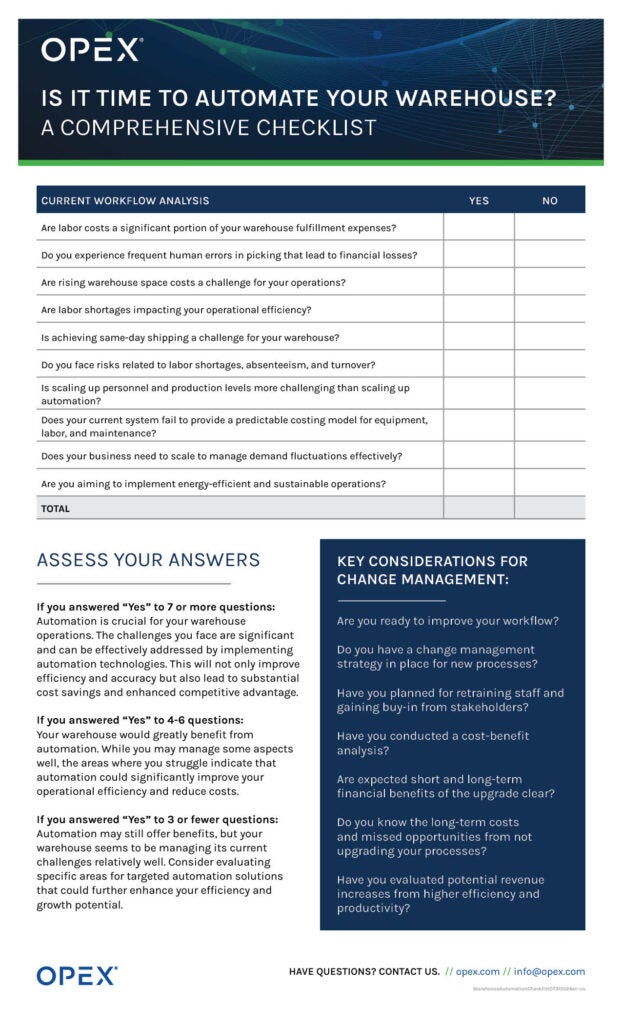

Deciding whether to automate your warehouse involves assessing your current needs and capabilities. Key questions include:

- How does your business need to scale to manage demand fluctuations?

- Can you utilize existing infrastructure to get closer to your customer?

- Are there opportunities to reduce shipping costs and improve delivery times?

- Can you eliminate non-value-adding steps in your current process?

Is it time to automate your warehouse?

Trends on the Horizon

Looking ahead, several trends are shaping the future of warehouse automation:

- Scalable Solutions: Systems that can adapt to changes in order volumes and storage needs without significant downtime are crucial.

- Advanced Robotics: Robots will become more sophisticated, capable of handling more complex tasks and making autonomous decisions based on AI-driven insights.

- Hyper-Personalization and E-commerce: As e-commerce continues to grow, warehouses will need to adapt to the increasing demand for personalized products and services.

- Sustainability: Automated systems will need to be energy-efficient, minimize waste, and optimize resource use to meet both regulatory requirements and consumer expectations for environmentally friendly operations.

In conclusion, the cost of not automating your warehouse is far greater than the initial investment in automation. Embracing these technologies not only mitigates current challenges but also positions your business for sustainable growth and competitive advantage in a demanding market.

Other Resources You Might Find Helpful

OPEX Service – The Ultimate Partner for Operational Excellence

Automating Kitting Operations

Sure Sort X with Xtract Tote I/O

OPEX® to Showcase the Latest Advancements in Warehouse Automation Solutions at ProMat Trade Show in Chicago

OPEX® Exhibits Next Generation Warehouse Automation Solutions in Germany During LogiMAT, Europe’s Largest Trade Show for Warehouse and Intralogistics

Last Exit Before Windows 10 End-of-Support: Is Your Document System Ready?

Why Warehouse Automation Service Models Matter

OPEX® Corporation Announces Key Enhancements to Infinity®

Revolutionizing Manufacturing Warehouses – OPEX® Perfect Pick®

World Class Technology. Local Expertise.

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.