Versatile, Scalable, Configurable & Cost-Effective Sortation

Sure Sort® X is an innovative application of our industry-leading automated sortation technology, empowering you to dramatically improve operational efficiency, save time and money, and continually exceed your customers’ expectations.

MEET Sure Sort X

This is Sortation to the Power of X

With nearly eight billion items sorted to date, Sure Sort leads the industry with its state-of-the-art product handling and throughput capability. Based on customer feedback, Sure Sort X has been redesigned from the inside out to provide a reliable and robust industrial solution to handle nearly 100% of customer-sortable products, including items 60% smaller, nearly 20% larger, and up to 4X heavier. This is sortation to the power of X.

iBOT® Delivery Vehicles

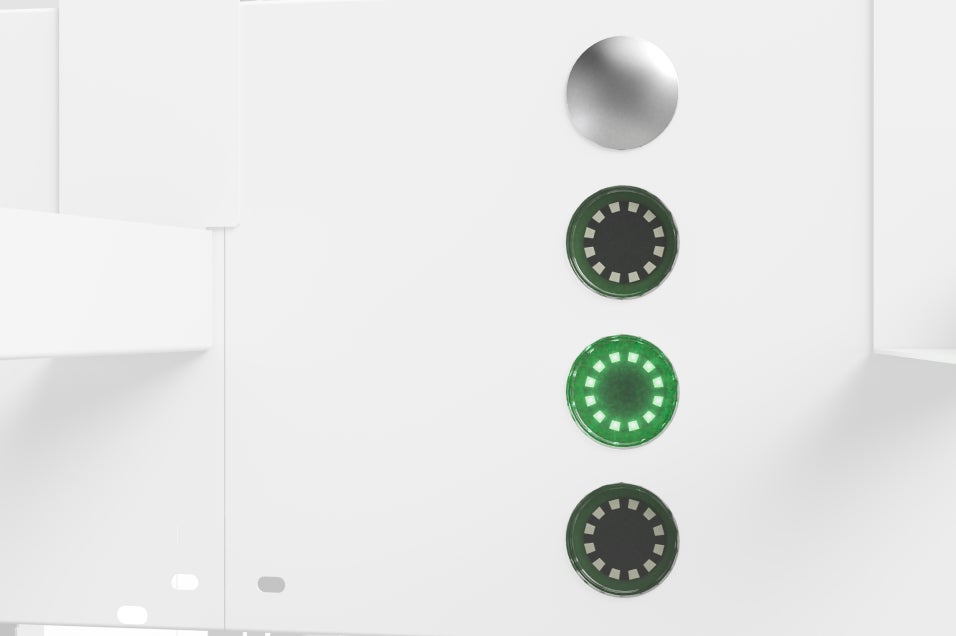

Pack-to-Light System

The unique pack-to-light feature identifies orders ready for packing with a customizable array of LED indicators.

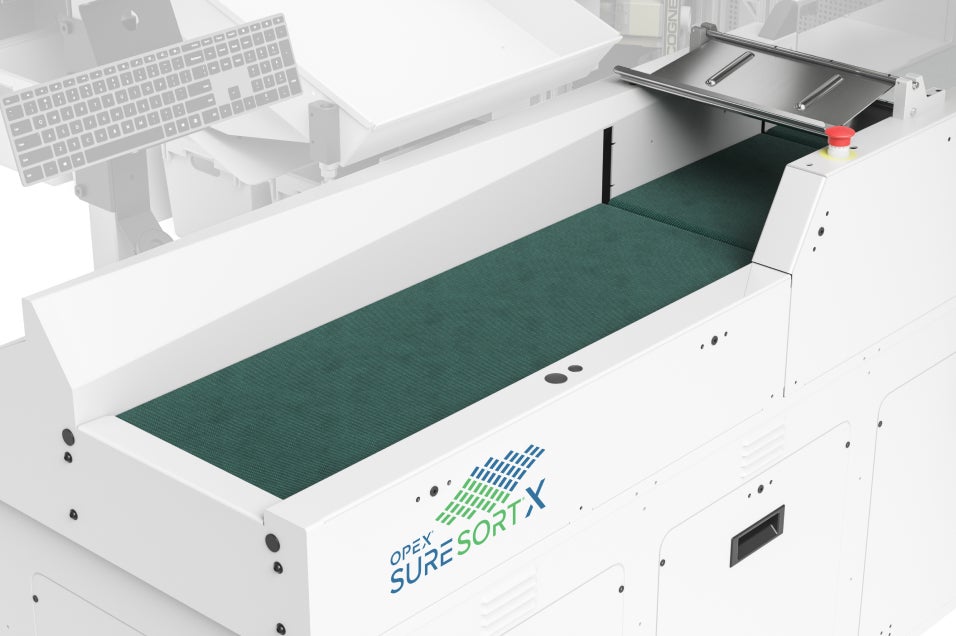

Induction Station

The drop conveyor automatically accelerates items for optimal delivery of up to one item per second. When items reach the scan tunnel, they are scanned on six sides by fixed-mount readers, and up to eight barcodes can be processed simultaneously.

Hand Scanner

Hard-to-read items can be manually scanned and processed via a convenient hand scanner, giving Sure Sort X the flexibility to adapt to your specific induction needs.

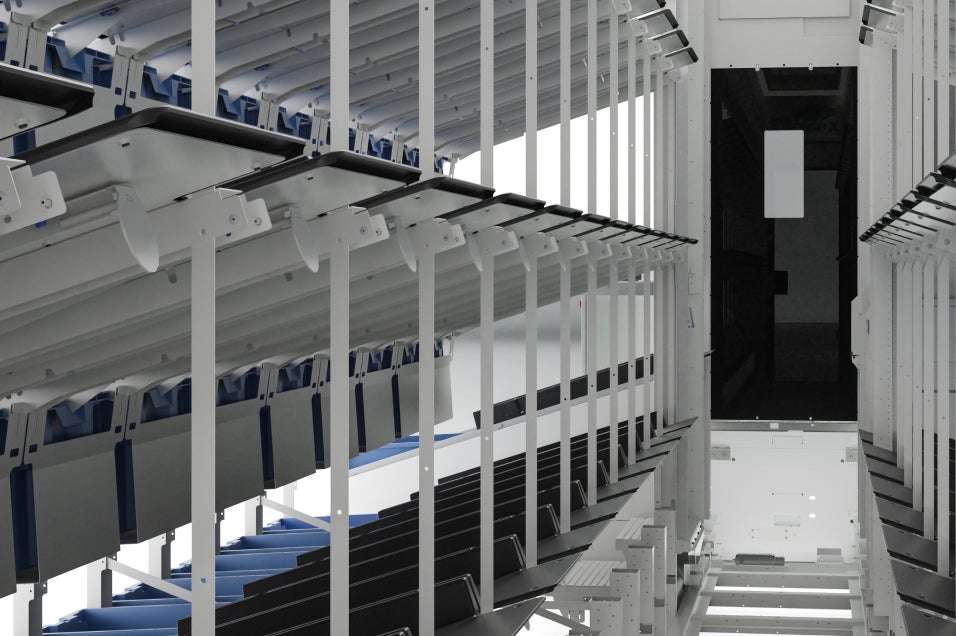

Variable Sort Locations

Products up to 18″ x 14″ (45.7 cm x 35.5 cm) are sorted into a configurable array of mixed and various bin sizes and types to best-fit customer needs.

Configurable Rack

Sure Sort® X’s configurable industrial racking is optimized for chilled and ambient environments and designed to accommodate various site layouts and workflows.

Sure Sort X |  Sure Sort |

|

|---|---|---|

| Length | 5.03 m up to 25.51 m; 1.46 m for each additional expansion module | 1.55 m up to 13.96 m 1.13 m for each additional expansion module |

| Width | 4.45m at the input conveyor; 3.39 m at the expansion module | 3.35 m at the input conveyor 1.77 m at the expansion module |

| Height | 3 m | 2.72 m |

| Environment | Chilled (31.1 °C Non-Condensing) to Ambient (32.2 °C Max) | |

| Sortable Item Length x Width Minimum | 3.2 cm x 3.2 cm or 2 cm2 | 5 cm x 5 cm or 25cm2 |

| Sortable Item Length x Width Maximum | 45.7 cm x 35.5 cm | 38.1 cm x 30.5 cm |

| Sortable Item Height | 0.03 cm to 20.3 cm | 0.017 cm to 15.24 cm |

| Sortable Item Weight | Up to 9 kg | Up to 2.27 kg |

| iBOTs | Up to 20 | Up to 22 |

| Delivery Bins/Totes/Boxes (Mixed & Various Sizes) | 13.5 cm, 21.6 cm, 27.2 cm, 36.3 cm; EU tote (600x400x300 mm); supports gaylord and delivery bag | 7.62 cm, 10.16 cm, 15.24 cm, 27.94 cm, 35.56 cm Supports gaylord, EU tote (600x400x300 mm), and delivery chute |

| Throughput | Scalable up to 2,100 items per hour | Scalable up to 2,400 items per hour |

| Barcode Readers | Up to 6-sided, automated OPEX scan tunnel Fixed mount readers Hand scanner RFID Batch scan | Up to 6-sided, automated OPEX scan tunnel Fixed mount readers Hand scanner RFID Batch scan |

| Optional Dimensioner | Captures product dimension from 10 mm with a resolution of 2.5 mm Cubic volume bin reporting with dimensioner | Captures product dimension from 10 mm with a resolution of 2.5 mm Cubic volume bin reporting with dimensioner |

| Automated Return Conveyor | Items recalled by WMS are returned for secondary action | Items recalled by WMS are returned for secondary action |

| Pack-to-Light | Customizable LED indicators | Customizable LED indicators |

| Expansion Modules | Up to 15 | Up to 11 |

| Induction Conveyor Location | Option to install on either the right or left side at the front of the system | Option to install on either the right or left side at the front of the system |

| Included Automation Interfaces | Ready to feed status, external e-stop, Machine Controls API, Order Creation Interface (S2O) | Ready to feed status, external e-stop, Machine Controls API, Order Creation Interface (S2O) |

| HMI Languages Supported | English, French, German, Italian, Japanese, Korean, Polish, Portuguese, Spanish |

Sure Sort X |  Sure Sort |

|

|---|---|---|

| Length | 16.5 ft up to 83.7 ft; 4.8 ft for each additional expansion module | 5.1 ft up to 45.8 ft 3.7 ft for each additional expansion module |

| Width | 14.6 ft at the input conveyor; 11.1 ft at the expansion module | 11 ft at the input conveyor 5.8 ft at the expansion module |

| Height | 9.8 ft | 8.9 ft |

| Environment | Chilled (34° F Non-Condensing) to Ambient (90° F Max) | |

| Sortable Item Length x Width Minimum | 1.25 in x 1.25 in or 2 in2 | 2 in x 2 in or 4 in2 |

| Sortable Item Length x Width Maximum | 18 in x 14 in | 15 in x 12 in |

| Sortable Item Height | 0.01 in to 8.0 in | 0.007 in to 6 in |

| Sortable Item Weight | Up to 20 lbs | Up to 5 lbs |

| iBOTs | Up to 20 | Up to 22 |

| Delivery Bins/Totes/Boxes (Mixed & Various Sizes) | 5.3 in, 8.5 in, 10.7 in, 14.3 in; supports gaylord and delivery bag | 3 in, 4 in, 6 in, 11 in, 14 in supports gaylord and delivery chute |

| Throughput | Scalable up to 2,100 items per hour | Scalable up to 2,400 items per hour |

| Barcode Readers | Up to 6-sided, automated OPEX scan tunnel Fixed mount readers Hand scanner RFID Batch scan | Up to 6-sided, automated OPEX scan tunnel Fixed mount readers Hand scanner RFID Batch scan |

| Optional Dimensioner | Captures product dimension from 0.4 in with a resolution of 0.1 in Cubic volume bin reporting with dimensioner | Captures product dimension from 0.4 in with a resolution of 0.1 in Cubic volume bin reporting with dimensioner |

| Automated Return Conveyor | Items recalled by WMS are returned for secondary action | Items recalled by WMS are returned for secondary action |

| Pack-to-Light | Customizable LED indicators | Customizable LED indicators |

| Expansion Modules | Up to 15 | Up to 11 |

| Induction Conveyor Location | Option to install on either the right or left side at the front of the system | Option to install on either the right or left side at the front of the system |

| Included Automation Interfaces | Ready to feed status, external e-stop, Machine Controls API, Order Creation Interface (S2O) | Ready to feed status, external e-stop, Machine Controls API, Order Creation Interface (S2O) |

| HMI Languages Supported | English, French, German, Italian, Japanese, Korean, Polish, Portuguese, Spanish | English, French, German, Italian, Japanese, Korean, Polish, Portuguese, Spanish |

Find Out How Sure Sort X Can Improve Your Operations

"*" indicates required fields

Sure Sort X Delivers Next-Generation Sortation

Sure Sort X is engineered to help businesses of all sizes improve the overall efficiency of their distribution operations and optimally position themselves for future success.

Unmatched Versatility

Unmatched Versatility

Sure Sort X supports virtually any mission-critical sorting application, including parcel sorting, kitting, cross-docking, returns processing, in-store fulfillment, and retail inventory management. Plus, it’s optimized to work in both chilled and ambient environments.

Efficient Throughput

Efficient Throughput

Sure Sort X achieves a throughput of up to 2,100 items per hour and requires minimal manual labor to function fully—even during peak seasons when order volumes or inventory turnover may be high. Larger and heavier items up to 20 lbs (9 kg) are sortable to a configurable array of mixed and varying bin sizes and types based on your unique needs.

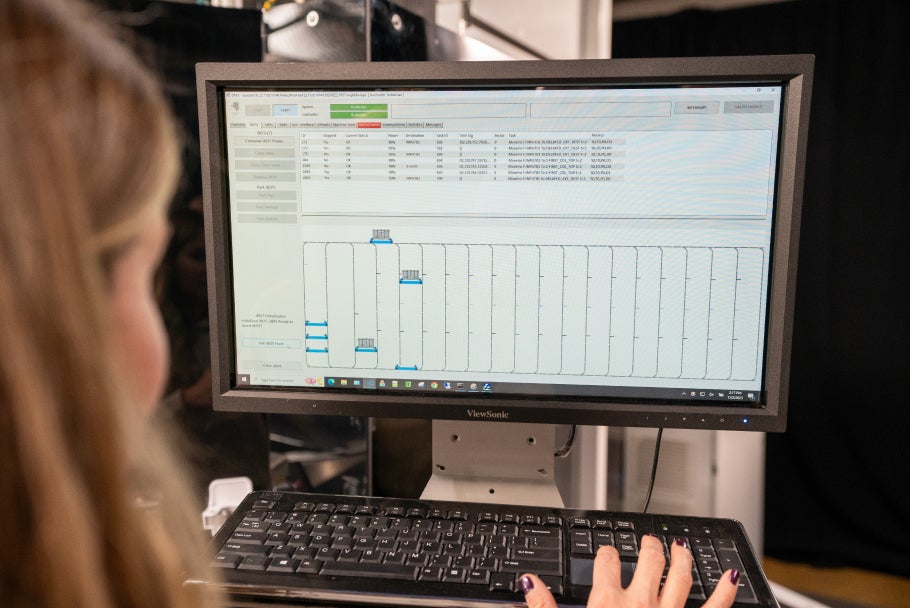

Effortless Integration

Effortless Integration

Sure Sort X is compliant with various North American and International standards and fully compatible with any Warehouse Control or Management System with no disruption to day-to-day operations. Sure Sort X is available with industry-leading delivery times of just 6-8 months.

Small Footprint

Small Footprint

Sure Sort X is compact and supports a wide variety of configurations, making it an ideal solution for micro-fulfillment centers with minimal floor space. The system’s modular design allows installation in as little as one week.

“OPEX WAS A TRUE PARTNER.

THE PERFECT PICK WAS INSTALLED AND OPERATIONAL EXACTLY AS PROMISED.”

Richard Davidson

Project Manager

Discover How Sure Sort X Has Impacted Other Operations

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.